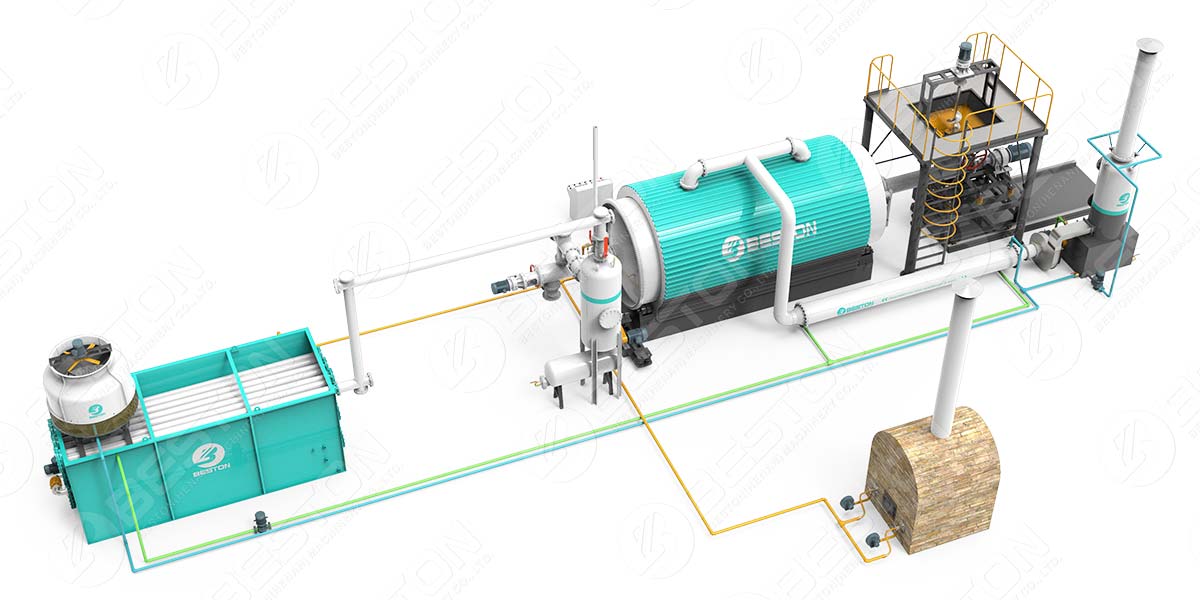

Continuous pyrolysis plants are one of the ideal ways to deal with waste such as plastic, rubber, medical waste, waste tyres, and oil sludge. These are plants that offer a host of benefits.

To begin with, these plants handle a capacity of 20-24t/d, which makes this equipment the perfect solution for large factories and businesses that need to discard or recycle large amounts of waste.

The pyrolysis plant for sale includes feeders that are automatic. This provides a way to automatically feed all the waste tyres easily into a reactor. This drastically lowers manpower and costs. The Continous Tyre Pyrolysis Plant also includes shredder equipment. These machines crush the rubber tyres into much smaller pieces of around 20mm. This assists with optimizing the overall efficiency relating to pyrolysis.

This equipment is also designed to continuously run for 24-hours without having to stop. It also has enough capacity to discharge slags and at the same time feed the materials directly into a reactor. When compared to traditional or manual versions of the pyrolysis plants, continuous plants will help to save on both time and fuel.

The most important advantage of a continuous pyrolysis plant is the stable reactor rather than a rotary type. This helps with more even and faster heating inside the reactor. Check the pyrolysis plant cost here.

The Working Process Of The Continuous Pyrolysis Plant

#1 Pre-Treatment

Before pyrolysis processes can begin, waste tyres must undergo the pre-treatment phase. This part involves the shredder equipment that breaks the waste down into much smaller and more manageable pieces of around 20mm.

#2 Feeding The Raw Materials

After the pre-treatment process, the waste is fed into the reactor automatically. The inlet door is also sealed tightly and securely to prevent gas leakages.

#3 Pyrolysis

The reactor will first be heated using a source of fuel. Some of these examples include charcoal, fuel gas, coal, or wood. The reactor will gradually get hotter. Once the temperature rises to 250℃, the process will produce oil gas.

#4 Condensing

Oil gas produced in the reactor is then sent to the condensing system, where the gas changes into liquid oil.

#5 Recovery Of Waste

Gas that doesn’t liquefy under a standard pressure is then sent to the combustion system. The recycled gas is then used as a fuel to heat the reactor, saving energy and fuel throughout the working process. More information on tyre pyrolysis plant here.

#6 Discharge

The carbon black and steel wire will be discharged automatically, and any of the waste materials are then returned to the pyrolysis reactor.

Final Products

– Tyre Oil

This oil is used widely as industrial fuel materials. It can also be refined further to diesel or gasoline, used in low-speed engines such as road rollers, digging machines, and loading machines.

– Carbon Black

This product is commonly used for building bricks that are made with clay. It is also frequently made into pellets or briquettes for burning. Want to get mini pyrolysis machine, see it.

– Steel Wire

The steel wire that is discharged during these processes, are recycled again and then used to produce steel rods and iron.