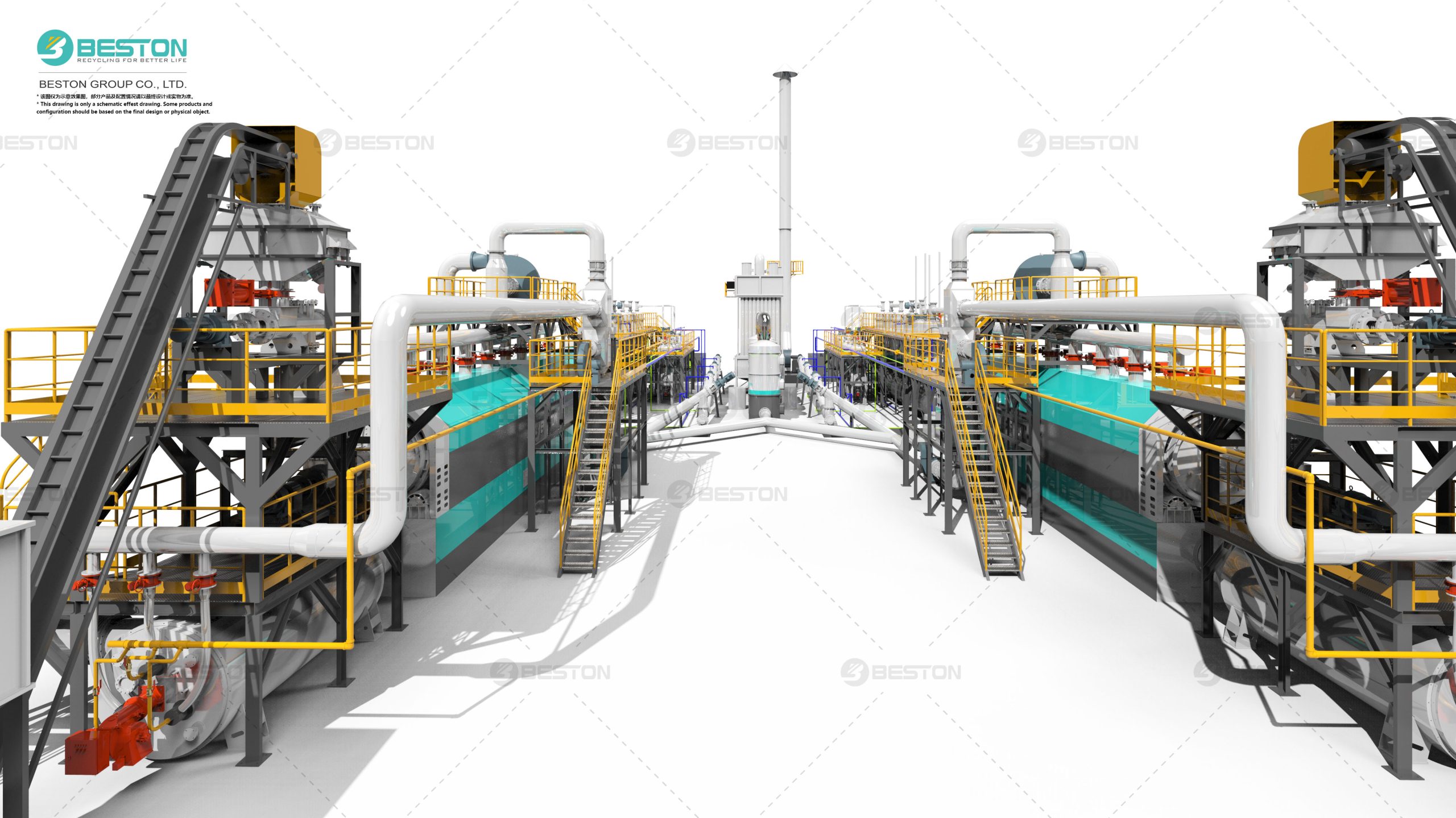

Waste management has long been a pressing global issue, with traditional disposal methods contributing to environmental pollution and resource depletion. In recent years, continuous pyrolysis technology has emerged as a game-changer in the field of waste treatment. This innovative approach not only addresses the challenges of conventional waste management but also brings forth a multitude of environmental benefits. In this in-depth exploration, we’ll delve into the intricacies of continuous pyrolysis equipment, its applications, and the far-reaching advantages it offers for a sustainable future.

Understanding Continuous Pyrolysis

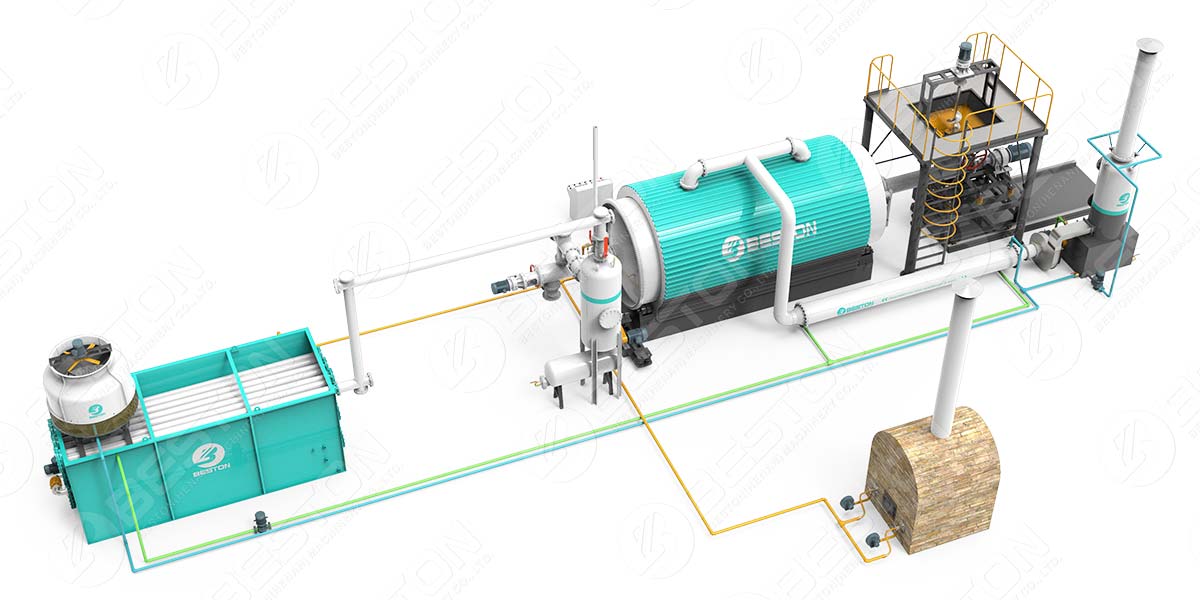

At its essence, pyrolysis is a process that involves the thermal decomposition of organic materials in the absence of oxygen. What distinguishes continuous pyrolysis from traditional batch pyrolysis is its uninterrupted and ongoing nature. In a continuous pyrolysis system, the feedstock is continuously fed into the reactor, ensuring a steady and efficient conversion of waste into valuable products.

Continuous Pyrolysis Process: Uninterrupted Transformation

Continuous Feedstock Introduction:

In continuous pyrolysis systems, a constant supply of feedstock is introduced into the reactor. This feedstock can include a variety of materials, such as plastics, biomass, and rubber.

Heating and Thermal Decomposition:

The reactor is heated to the required temperature, typically ranging from 400 to 800 degrees Celsius. The absence of oxygen ensures the thermal decomposition of the feedstock, releasing volatile gases and vapors.

Continuous Gas and Vapors Collection:

The released gases and vapors, containing valuable components like syngas and bio-oil, are continuously collected. This constant extraction ensures a steady stream of these valuable byproducts.

Solid Residue Generation:

The solid residue, often referred to as char or carbon black, is continuously generated as a byproduct of the process. This char can be further processed for various applications, including soil improvement.

Continuous Condensation:

The vapors are continuously condensed to obtain liquid bio-oil. This versatile substance can be used as a precursor for biofuels, chemicals, and other industrial purposes.

Syngas Cleaning and Collection:

The syngas, a mixture of hydrogen, carbon monoxide, and other gases, is continuously cleaned to remove impurities. The purified syngas can then be used for energy generation or as a feedstock for the production of chemicals. The small pyrolysis unit also has an emission gas cleaning system.

Continuous Residue Handling:

The remaining char is handled in an ongoing manner, with potential applications ranging from carbon sequestration to the creation of valuable products like activated carbon.

Environmental Benefits of Continuous Pyrolysis

Reduced Emissions:

Continuous pyrolysis systems operate with high efficiency, minimizing emissions of harmful pollutants compared to traditional waste disposal methods. The absence of oxygen during the process contributes to lower carbon dioxide and methane emissions.

Energy Efficiency:

The continuous nature of the pyrolysis process allows for a more efficient use of energy resources. The steady production of syngas facilitates consistent energy recovery, making continuous pyrolysis a viable option for sustainable power generation.

Resource Recovery:

Continuous pyrolysis maximizes resource recovery by providing a continuous stream of valuable byproducts. This includes syngas for energy, bio-oil for industrial applications, and char for soil improvement.

Land Use Optimization:

Continuous pyrolysis systems can be designed for varying scales, enabling optimization of land use for waste treatment. This is particularly crucial in urban areas where space is limited, and efficient waste management is imperative.

Continuous Innovation:

The ongoing nature of continuous pyrolysis technology fosters continuous innovation. Research and development efforts are constantly improving the efficiency and environmental performance of these systems, ensuring a dynamic and evolving solution to waste management challenges.

Applications of Continuous Pyrolysis Technology

Plastic Waste Management:

Continuous pyrolysis is particularly effective in the continuous conversion of plastic waste into valuable products. The steady process allows for a constant flow of syngas and bio-oil from plastic feedstock.

Biomass Valorization:

Biomass, including agricultural residues and forestry waste, can be continuously processed using pyrolysis. This facilitates ongoing biochar production, contributing to soil improvement and carbon sequestration.

Tire Recycling:

Continuous pyrolysis has shown promise in the continuous recycling of used tires. The process generates a constant supply of valuable outputs, including bio-oil and recovered carbon black.

Municipal Solid Waste Treatment:

The ongoing nature of continuous pyrolysis is well-suited for municipal solid waste treatment. It provides a constant and efficient means of converting diverse waste streams into valuable resources.

Challenges and Future Outlook

Technological Advancements:

Continuous pyrolysis technology is still evolving, and further advancements are needed to enhance efficiency, reduce costs, and optimize resource recovery.

Feedstock Variability:

The quality and composition of feedstock can vary, presenting challenges in maintaining continuous and stable pyrolysis processes. Research is ongoing to develop systems that can handle diverse feedstocks seamlessly.

Economic Viability:

While continuous pyrolysis offers numerous environmental benefits, its economic viability remains a consideration. Continued research and development are essential to bring down initial costs and operational expenses.

Regulatory Framework:

The establishment of clear and supportive regulatory frameworks is crucial for the widespread adoption of continuous pyrolysis technology. This includes standards for emissions, safety, and waste handling.

Conclusion

Continuous pyrolysis technology represents a significant step forward in the quest for sustainable and efficient waste management solutions. By providing a continuous and uninterrupted transformation of waste into valuable resources, this technology offers a promising avenue for addressing environmental challenges associated with traditional waste disposal methods. As research and development efforts continue to refine and advance continuous pyrolysis systems, the potential for widespread adoption grows, paving the way for endless environmental benefits and a more sustainable future. Contact tyre pyrolysis plant suppliers for more industry information.