Industrial packaging is any type of packaging that’s primarily made for companies that deal in the manufacture of glass, machinery, parts, products, and other items that are bought by consumers or other businesses to repair or make something. In simpler terms, industrial packaging is any type of packaging that’s used to package items that are not final goods or consumer goods.

Since packaging plays a vital role in securing and protecting products as they are being stored or transported, it is essential for any company that deals in the manufacture of different goods and items to consider investing in the right packaging for the shipment and storage of its goods. If you are currently shopping for a reliable industrial packaging solution, then this guide is here to help you find and choose the perfect industrial packaging solution for your business.

Packaging options

For starters, it is worth noting that many different types of packaging materials are used to make industrial packaging. Available options include:

Foam Packaging: Because it provides cushioning and protects fragile products during shipping, foam is one of the most effective types of packaging material available.

Corrugated Cardboard Packaging: Corrugated cardboard packaging is a reliable and recyclable option that’s generally used to provide extra cushioning around a product.

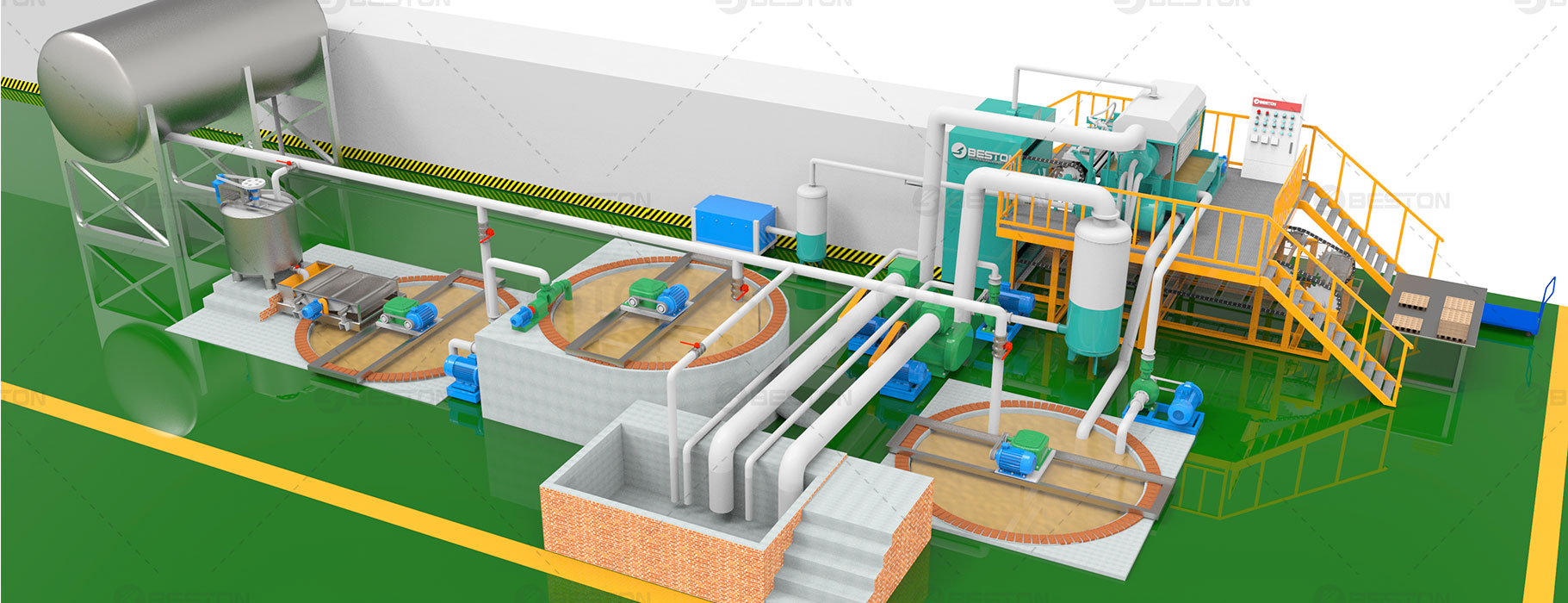

Molded Pulp Packaging: This option is designed to effectively hold products in place and cushion them from impact. It is mostly used in industries that deal with electronics or have specific packaging requirements. Here are details: https://bestonasia.com/egg-tray-manufacturing-machine/.

Void-Fill Packaging: This type of packaging fills the space between goods or products and their outer packaging with paper, plastic air bubbles, or foam. It’s generally used to ensure products or goods are secure and don’t move around.

Thermoformed Plastic: This option is great for single-use packaging.

Reusable Plastic Corrugated: This packaging is used in reusable applications and for storage.

Molded Containers: Ideal for material handling and frequent usage.

Factors to Consider When Choosing an Industrial Packaging Solution

When choosing an egg tray machine, there are several crucial factors that you need to consider, especially when it comes to the product you are packaging, the end user, and the packaging’s lifespan. Factors to think about include:

What Are You Packaging?

Your product’s composition, weight, application, and size will all impact the decision you make when choosing industrial packaging. For instance, wooden packaging alone isn’t ideal for extremely fragile or small items like glass components. On the other hand, using foam to package large pieces of machinery just isn’t economical.

Why You Need to Package It

The other thing you need to consider is why you need the product packaged, whether that be for moving and storing it internally or for shipping it to an end user. There are industrial packaging solutions that are best suited for internal usage and others for one-time shipping use.

The Package’s Environment

Another thing you need to consider is the package’s environment once you’ve packaged your product. For instance, if you believe the packaging will spend a lot of time in a damp environment, corrugated cardboard packaging won’t cut it for you. Therefore, you need to make sure that the option you pick corresponds with whatever you are shipping and the conditions it’ll be subject to during shipping.

The Item’s End-User

When choosing industrial packaging, make sure you also consider the item’s end user and go for an option that makes sense for their needs, environments, and values.

Your Budget

As a business, you want a pulp molding machine that not only protects your items but also survives the journey to your customer and is affordable. When choosing an industrial packaging solution that works for you, consider mixing up the packaging materials and options to lower costs while providing your product with the protection it needs.

Choose a Solution that Works Best for You

The right solution when considering different industrial packaging options for your items will be determined by a host of factors. To ensure that you make the right decision and pick the right packaging solution, make sure that you consider all of the factors mentioned above.