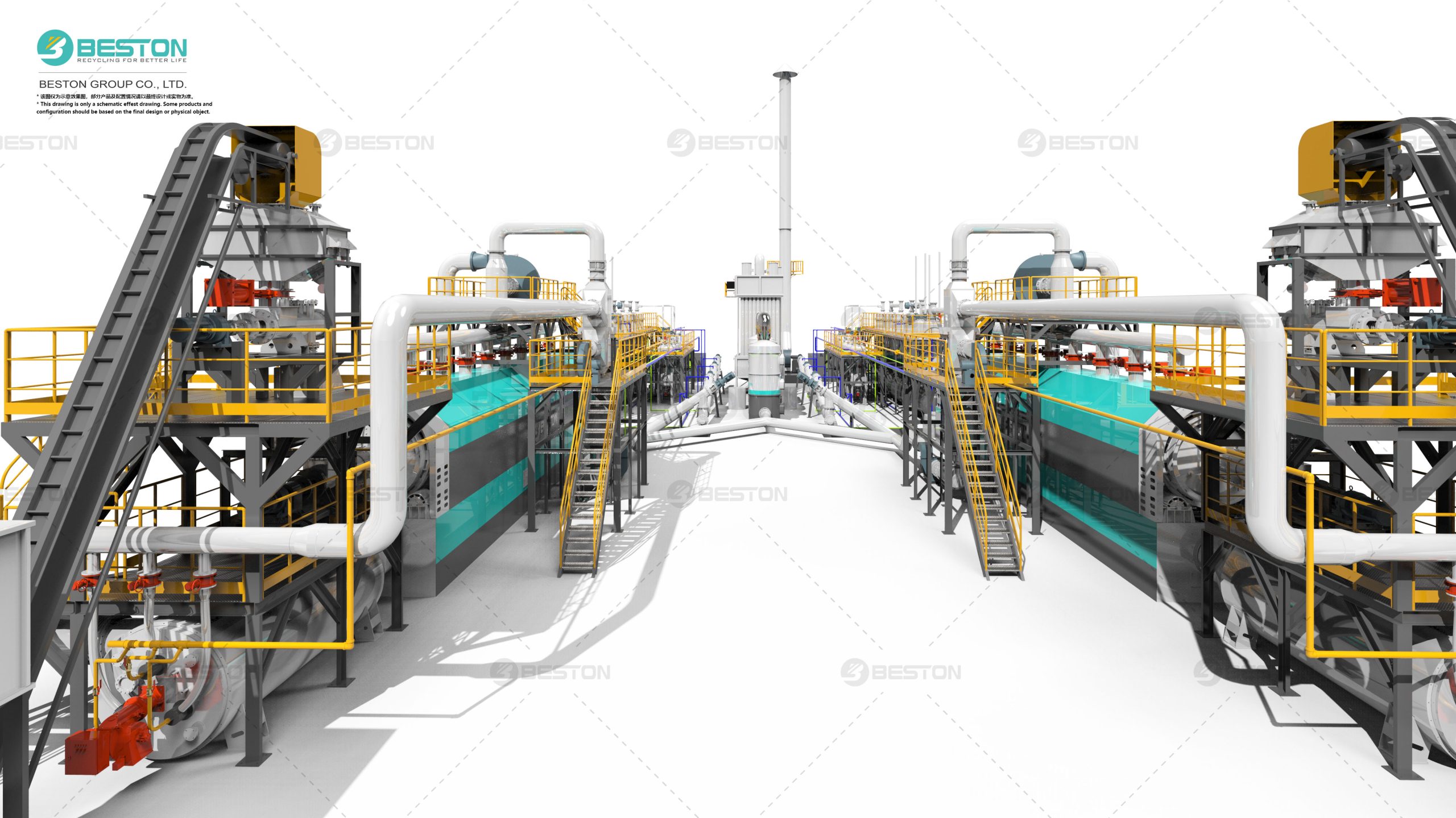

You need to find a Beston paper tray machine that is put together by professionals. It needs to be top of the line and worth the money you’re spending on it. That will allow you to know that you have something on hand that is going to last you a long while.

Once you know you want this kind of machine (máquina para hacer cartones de huevos en colombia), make an effort to look at what Beston has to offer on the market. That way, you can put together a list of what you want to learn a little more about. Sometimes, you will find that some options are better than others and that’s why you want to make sure you learn a bit about each of the options that you have to select from. It’s easy to pick out what you know is the best once you know a bit more. Don’t buy something at random if you want good results.

Know where you’re going to order your paper tray materials from when you have a machine on hand. You need to know exactly what you’re going to have to pay to get the right materials so you know if a machine is going to be worth using. It’s wise to know how much it costs to make paper trays (máquina para hacer cubetas para huevos) because then you can factor that price into what you’re selling the finished product for. It’s best to do the math before you spend anything so you don’t end up losing money on your project in the end.

There are usually plenty of reviews on the internet that you can look at if you want to know what to spend your money on. If a lot of people tell you that something is a solid machine, you will know that it’s probably going to be worth putting money towards. Even if a machine is well priced, that doesn’t mean that it’s a good deal because if it’s low in quality then it’s likely to fall apart on you. It’s best to just go with what others have had a lot of success with since it’s likely you will, too.

See the machine (https://www.bestoneco.com/btf1-4-maquina-para-hacer-bandejas-de-huevos-enviado-a-peru/) you’re going to buy in person before you buy it, when possible. That way, if there is any damage that you can see, you can speak with the seller about giving you a discount of some kind so you can use the money you save to get the machine into god working order. Don’t buy something used without learning what condition it’s in so you don’t waste money on accident. Some sellers are going to try to push machines on you that are not in the best of shape and that is why looking it over first is wise.

Start looking for a Beston (beston machinery) paper tray machine with the above advice in mind. It will make it a lot easier for you to find what you need without it taking a long time. Just do a lot of research and it shouldn’t take too long to come out ahead.